Should I Clean My Fiber & Connections?

To clean or not to clean... that is the question. TechLogix is often asked whether cleaning fiber is necessary. Some manufacturers claim it's not, others claim it's critical and failure to do so will void your warranty. So what's the reality?

The answer is easy -- yes, there is a benefit to cleaning both the optical fiber strand during installation and your optical connections, including connectors and electronic ports. This article explains why.

Fiber is Built for Cleanliness

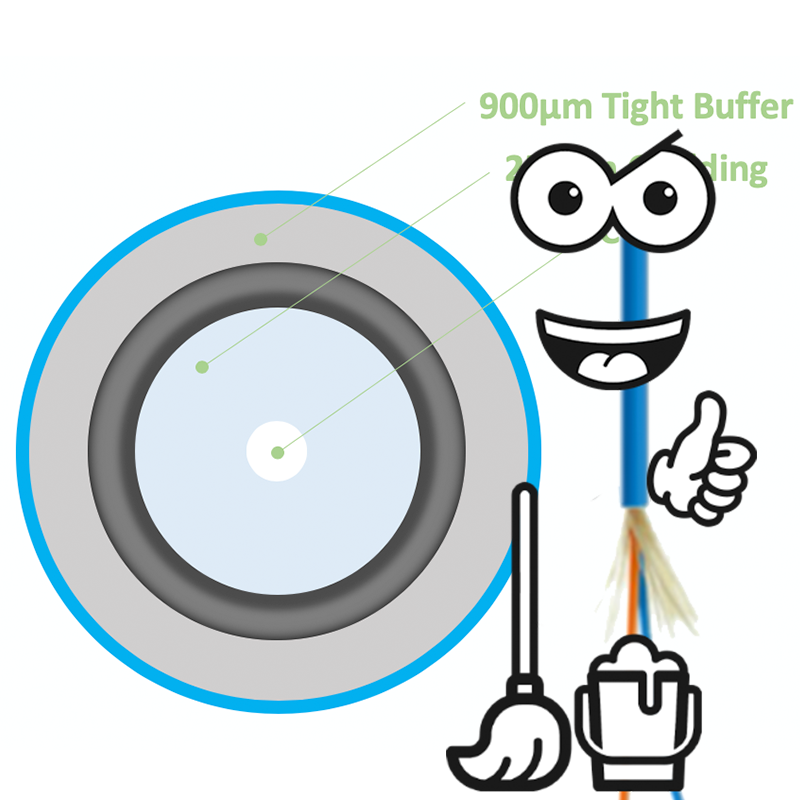

In order to understand the benefit of cleaning, it's important to understand the construction and implementation of fiber optic cabling.

First, fiber optic strands are incredibly small. Single mode fiber relies on a core diameter of 9 microns (or µm) and multimode fiber relies on a core diameter of 50 microns. For perspective, human hairs average between 17 and 180 microns. That's tiny...

Second, fiber-based systems rely on the clean transmission of light over those small optical strands and any contamination can disrupt the signal leading to loss and intermittent (or complete lack of) performance. The below image shows optical lenses affected by common contaminants when viewed through a microscope.

And contaminants don't just muck up the optical lenses. Fiber is typically installed in uncontrolled environments that can exasperate issues caused by dirt, oil, moisture and other detritus. Temperature fluctuations, including those from the heat output of the optical port on electronics, can lead to small misalignments that have a significant impact on signal loss. And, frustratingly, these misalignments often fluctuate with the temperature creating intermittent signal loss.

When integrating fiber-based systems, it's imperative that connectors, electronic ports, and any inline installation accessories such as patch panels, couplers, wallplates and adapters are clean to avoid loss from reflectance and signal dispersion within the fiber link.

Cleaning Optical Lenses & Ports

So what's an integrator to do? Well, let's start by discussing the optical connections.

Manufacturers are keenly aware contaminants will detrimentally affect a fiber-based system and dust caps are a standard feature on connectors, pre-terminated cables, couplers, electronics and other installation essentials. Dust caps should be kept in place as long as possible.

But what if you're servicing a retrofit with existing, pre-installed equipment? Or if the environment is particularly dusty, dirty or outdoors? Dust caps can't help an already compromised connection.

A click-style, also known as pen-style, cleaning tool is essential for any installer. Click cleaners use a special dust-free full contact cleaning process to remove contaminants on both fiber connectors and ports. They're easy to use -- simply "click" them on the connector and port ferrule. The only catch is they're specific to 1.25mm and 2.5mm ferrule sizes so you'll likely need one for LC connections and one for SC, FC, and ST connections.

If a click cleaner isn't available, traditional alcohol, wipes and swabs can and should be used.

Cleaning Strands During Termination

As outlined above, it's equally important to clean the fiber optic strand during termination regardless of strand construction.

Even the smallest amount of oil, moisture, dust or dirt can cause misalignment of optical strand within the connector housing leading to signal loss. A simple swipe from a lint-free alcohol wipe will help avoid this.

Isopropyl alcohol and cellulose-free wipes are typically recommended and are very low cost.

Bottom line: your customers rely on you to provide a high-speed, high-bandwidth cable infrastructure that will perform reliably for decades. Fiber future-proofs... why compromise it's performance by lack of cleaning. It adds less than $0.15 per connection and takes seconds.

Comments