Best Practices for Pulling Fiber Optic Cable

Fiber optic cable is surprisingly strong, durable and pliable; however, several best practices should be followed to ensure a successful cable installation. This article explores recommendations for pulling and installing fiber optic cable.

Pulling Fiber

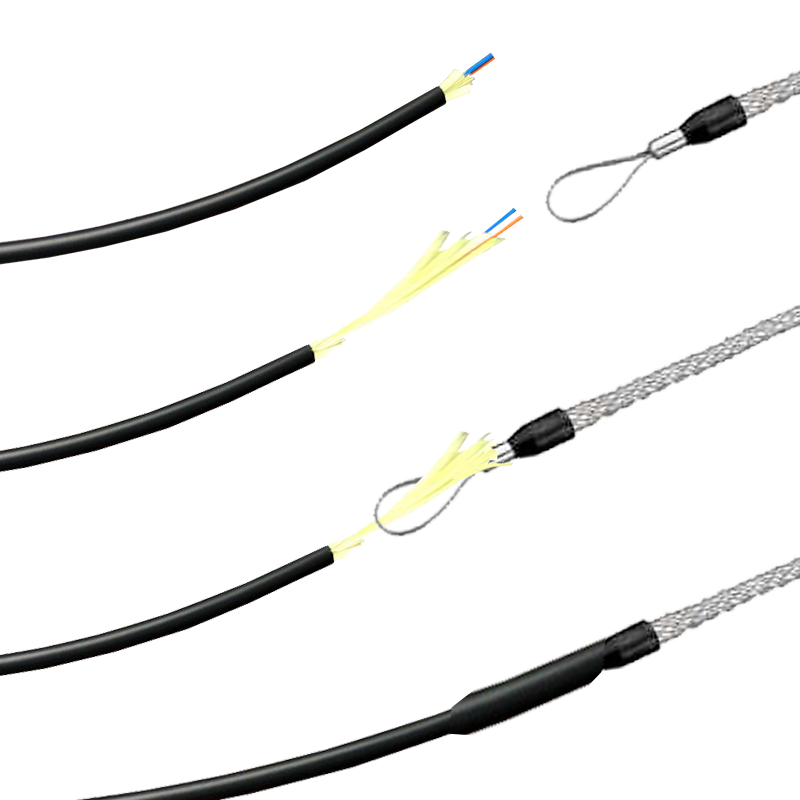

Most fiber optic cables boast a pull strength of 100 - 200 pounds thanks to the internal kevlar or aramid yarn, known as the strength member.

The most common mistake made when pulling fiber is failing to leverage the strength member. Many installers pull fiber by the outer jacket which is prone to stretch, tear and ultimately break. It's not uncommon to see an improperly pulled cable's jacket stretch several meters due to strain placed on the outer jacket, and a stretched jacket won't provide a secure termination thereby compromising the fiber inside.

Fiber optic cables should always be pulled by the strengthened yarn fibers inside the outer jacket. This strength member can be exposed by removing a small portion of the jacket with a three-hole cable stripper.

Once exposed, the yarn can be looped inside a cable pull-eye and double-backed and taped or knotted for security.

Bend Radius

Fiber optic cables are surprisingly pliable. In fact, the glass cores in modern cables provide minimum bend radiuses that far exceed twisted pair cables and other copper-based low voltage cables.

Modern bend-insensitive fiber cables, such as those manufactured with Corning ClearCurve® and SMF-28 Ultra® optical glass, feature minimum bend radiuses of 4.4mm (0.18in).

Older fiber optic cables, such as those using OS1 and/or OM1 optical glass, are more prone to breakage and a minimum bend radius of 30mm or more should be adhered to.

Cleaning Fiber & Connections

Fiber-based electronics rely on optical light waves and dirty connections will significantly affect signal performance. Contaminants such as dust, oil and pollen can collect on the optical lenses of cables, electronic ports and installation accessories, creating signal drops and/or loss of signal altogether.

Fiber optic connectors, cables, electronics and installation accessories ship with dust caps to ensure optical lenses remain clean during installation and handling. It's best practice to keep the dust caps in place as long as possible to avoid contamination.

If optical lenses do become contaminated, they can be cleaned using fiber alcohol wipes and/or "pen-style" or "click" cleaners.

Comments